Data Sheet

|

|

||

| ¡¡ | ¡¡ |

Data Sheet |

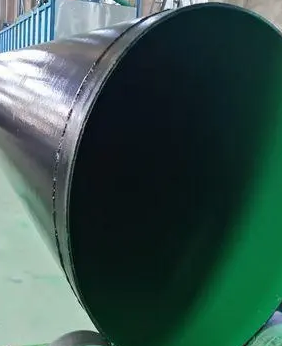

DTK-69 Inner-Coated Powder for Transmission Pipe

Properties and Applications

DTK-69 is a thermosetting epoxy powder coating for inner coater of pipeline. It meets with PC8007 red primer to make

high-quality coating. Which have the tough, excellent flexible, high impact resistance, high gloss, thick-film coating for

secondary and recovery system, particularly CO2.

The coating surface is very smooth, which greatly improves the hydraulic efficiency of the pipeline system. It is very

suitable for CO2, injection, oil and gas, sewage and other working conditions that need to improve corrosion resistance.

The coating layer thickness is generally more than 250 microns, and it is applicable to all kinds of transmission pipes,

sliding sleeves, fittings, etc. below 130¡æ (266 F).

Main Specification

|

No. |

Item |

Specifications |

Method |

|

1 |

Color |

Greed |

Visual |

|

2 |

Curing time¡ô |

235¡ãC, 45~60min |

|

|

3 |

DSC |

120¡ãC¡ÜTg2¡Ü135¡ãC ¦¤Tg<= ¡À2¡ãC |

CSA Z245 Clause 12.7 |

|

4 |

Coating thickness |

250~500um (10~20mil) 250~800um (10~32mil)£¬Custom |

NACE TM0185-2006 |

|

5 |

Service temperature |

¡Ü130¡ãC(266 F) |

|

|

6 |

Service pH range |

4-11 |

|

|

7 |

Coating roughness |

¡ÜRa1.6um (Rz6.3umor ¨Œ6) |

|

|

8 |

Abrasion resistance |

<50 mg £¬TABER Abraser [CS-17,1kg,1000r] |

ASTM D4060 |

|

9 |

Impact resistance |

5J |

ISO 6272-1 |

|

10 |

Adhesion |

Pull-off test£º>25 MPa X cutting method£º5A |

ISO 4624 ASTM D3359 |

|

11 |

Autoclave tests |

No blistering, cracking, swelling or softening or loss of adhesion |

|

2. Features

|

Recommended Service |

Benefits ¡¡ |

|

Oil and gas Transmission pipeline CO2/injection/oil and gas/sewage pipeline Chemical pipeline and fittings ¡¡ |

Excellent tough, flexible Excellent adhesion Wide temperature and pH range of 4-11 ¡¡ Good corrosion resistance High Gloss, Improve hydraulic efficiency High impact resistance ¡¡ |

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

3. Autoclave tests

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

|

No. |

Test Medium |

Test Temp. |

Test Pressure |

Test Time |

|

1 |

30%CO2, 70%N2 5%NaCl Solution |

130ºC |

10MPa |

24H |

|

2 |

10%H2S£¬40%CO2,50%N2 5%NaCl Solution |

130ºC |

10MPa |

240H |

|

3 |

50%CO2,50%N2 5%NaCl Solution |

130ºC |

10MPa |

240H |

|

4 |

0.5%H2S,5%CO2,94.5%N2 5%NaCl Solution |

130ºC |

3MPa |

1000H |

|

5 |

5% H2S,25% CO2,70%CH4 5%NaCl Solution |

130¡æ |

3MPa |

750 H |

¡¡

Note:

1.Above values are the accumulative typical ones by recognized testing method, but, in order to ensure you to

select our products properly, please refer to above specification and test the samples based on your using

purpose or feel free to contact our engineers for further and better understanding.

____________________________________________